September 12, 2021

What Are Influencers and How Can They Help My Brand?

Influencers are individuals, organizations, businesses, and brands that create a significant influence over a target audience. They use social media…

November 20, 2021

What Does a Bald Eagle Eat?

The bald eagle, the symbol of the United States is an interesting raptor that is generally found near large water…

January 19, 2024

A Day in the Life of a Pain Management Specialist

Ever imagined managing pain as a profession? For a Pain Management Specialist like me, it’s a daily reality. From dawn…

September 10, 2022

Find Love at Lightning Speed: Sydney’s Top Speed Dating Events

So you’re single and looking for love. But where do you start? There are so many dating apps and websites…

September 29, 2021

Fish oil supplements: Overview, uses, and benefits

Fish oil is oil gotten from the flesh of oily fish. It contains omega-3 fatty acids. For those who do…

December 20, 2021

8 Ways You Can Get Lean Six Sigma Black Belt Certification

Certified Six Sigma Black Belts and those who have received Six Sigma Black Belt training are in great demand all…

May 24, 2023

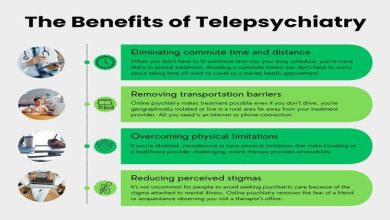

The Importance of Finding the Right Psychiatrist

When it comes to mental health, finding the right psychiatrist is essential. Whether you’re looking for therapy, medication management, or…

September 21, 2021

All Information From India’s Trade Portal

What is a trade portal? An internet site that offers records for groups in a selected industry and hyperlinks to…